Last Updated on July 25, 2025 by Muhammad Ramzan

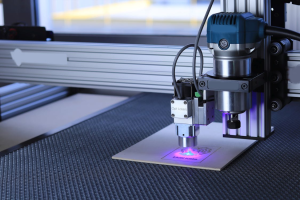

In modern manufacturing, speed, precision, and efficiency are more important than ever. That’s where fiber laser cutting machine comes into play. These high-performance tools have revolutionized the way industries handle metal processing, offering faster cuts, cleaner finishes, and lower operating costs compared to traditional methods. Whether you run a fabrication shop, an automotive production line, or a precision job shop, understanding the full scope of fiber-laser advantages can help you make an informed investment. Below are the factors—now explored in even greater detail—that prove why fiber laser cutting machines are a wise choice for businesses of every size.

Here Are Factors That Make Fiber Laser Cutting Machines A Smart Choice

Exceptional cutting speed

Fiber laser cutting machines are built for speed. Unlike older CO₂ lasers, fiber units operate at noticeably higher feed rates, particularly on thin to medium sheet metals. A 1 kW fiber laser can slice 1 mm stainless steel at well over 30 m/min, while higher-power models push that envelope even further.

By completing jobs in a fraction of the time, you can quote tighter lead times, open new production slots, and accept rush orders without overstretching your crew, directly improving customer satisfaction and revenue potential.

High precision and accuracy

For intricate geometries and tight tolerances, fiber technology is hard to beat. The solid-state laser beam remains perfectly stable, eliminating the subtle drift that plagues older gas lasers. Coupled with closed-loop servo controls and advanced motion systems, you achieve kerf widths as small as 0.1 mm.

That kind of repeatability means fewer rejected parts, less rework, and more predictable scheduling. In sectors like electronics or medical device housings, where every micron matters, such accuracy can be the difference between winning and losing the contract.

Low operating costs

Fiber lasers boast wall-plug efficiencies above 30%, dwarfing the 10% efficiency of many CO₂ systems. Lower energy draw directly cuts monthly utility bills. Further, the sealed fiber source has no mirrors to align and no laser gas to replace.

Add in air-assisted cutting (possible on many thin sheets), and you reduce the cost of bottled nitrogen or oxygen. When maintenance downtime shrinks from days to hours each year, staff productivity stays high, and your overall cost-per-part drops dramatically.

Versatility across materials

A single-fiber laser cutter can switch from stainless steel to brass with a quick parameter change. Aluminum alloys, galvanized sheets, even reflective copper—all are fair game. That versatility enables shops to diversify the customer bases without purchasing multiple machines.

It’s also ideal for custom job shops handling varied projects daily. From prototypes to large production runs, the ability to cut multiple materials without tooling changes keeps operations agile. For OEMs, a single machine that covers multiple materials simplifies training and machine-floor layouts, eliminating the space and cost penalties associated with dedicated cutting cells.

Clean, quality cuts with minimal waste

Smooth, burr-free edges reduce or eliminate the need for downstream grinding and deburring. When parts move straight from the cutter to welding or assembly, you compress your production timeline.

Precision nesting software—often bundled with machine purchases—packs parts tightly, slashing raw sheet consumption. This optimization not only reduces waste but also lowers inventory costs and increases material yield. Over the course of a year, the material savings alone can offset a major portion of the machine’s finance costs, especially for high-volume manufacturers working with metals like stainless steel or aluminum.

Compact, space-saving design

Floor space is pricey. Modern fiber systems combine the power source, chiller, and dust extractor into a tight footprint, sometimes half the size of older CO₂ setups. Some models fit through a standard shop doorway and require only a single electrical drop, easing installation.

This makes them ideal for workshops with limited space or those transitioning from manual to automated processes. Their modular design also allows for easier relocation or integration into existing lines. For growing businesses in urban areas, that compactness can delay or eliminate the need for costly facility expansions while still scaling production capabilities efficiently.

Automation & smart controls

Touch-screen HMIs now mirror the intuitive feel of smartphones, featuring pinch-zooming, swipe menus, and customizable dashboards. Auto-focus heads adjust pierce height and focus depth on the fly, letting operators queue mixed-thickness jobs without manual nozzle swaps.

Modern fiber laser systems often feature intelligent fault detection, predictive maintenance alerts, and integrated cameras for process monitoring. Integrate the laser with ERP software, and you gain real-time progress tracking and automatic job reporting, both of which are crucial for lean manufacturing initiatives. These tools reduce operator error, improve uptime, and streamline batch production workflows, making even complex jobs more straightforward to manage.

Environmental efficiency

Fiber lasers operate at a lower temperature and produce less noise, creating a safer and more pleasant workspace. With no resonator gases vented to the atmosphere and far lower electricity demand, you lower your carbon footprint—an increasingly important metric when bidding for eco-conscious customers or complying with CSR targets.

Additionally, many modern systems feature energy-saving modes and efficient dust collection units, thereby minimizing waste and airborne particles. Their sealed design also means fewer consumables and less frequent part replacements, reducing the overall environmental impact. For companies seeking to meet green manufacturing standards, fiber lasers provide both performance and sustainability in a single package.

Strong return

Combine faster cycle times, lower scrap, minimal maintenance, and energy savings, and many shops see payback in as little as two to three years. Because fiber lasers retain high resale value, even machine upgrades are less risky—trading in an older unit can offset a significant portion of a new purchase, keeping you on the cutting edge without incurring substantial capital expenses.

Additionally, their long service life and consistent output quality ensure reliable performance for years, maximizing your return well beyond the initial investment. As demand for precision fabrication continues to rise, owning a fiber laser cutter also positions your business for long-term growth and diversification.

The Final Thoughts

Selecting the right cutting technology shapes everything from job-shop agility to long-term profitability. Fiber laser cutting machines deliver across the board—speed, accuracy, low operating cost, material versatility, and environmental responsibility. If you’re weighing an upgrade, examine your current bottlenecks: Are turnaround times tight? Is edge cleanup adding overtime? Are energy bills climbing? A fiber laser could be the answer. By embracing this future-ready technology, you’re not just buying a machine; you’re investing in faster workflows, happier clients, and a healthier bottom line.